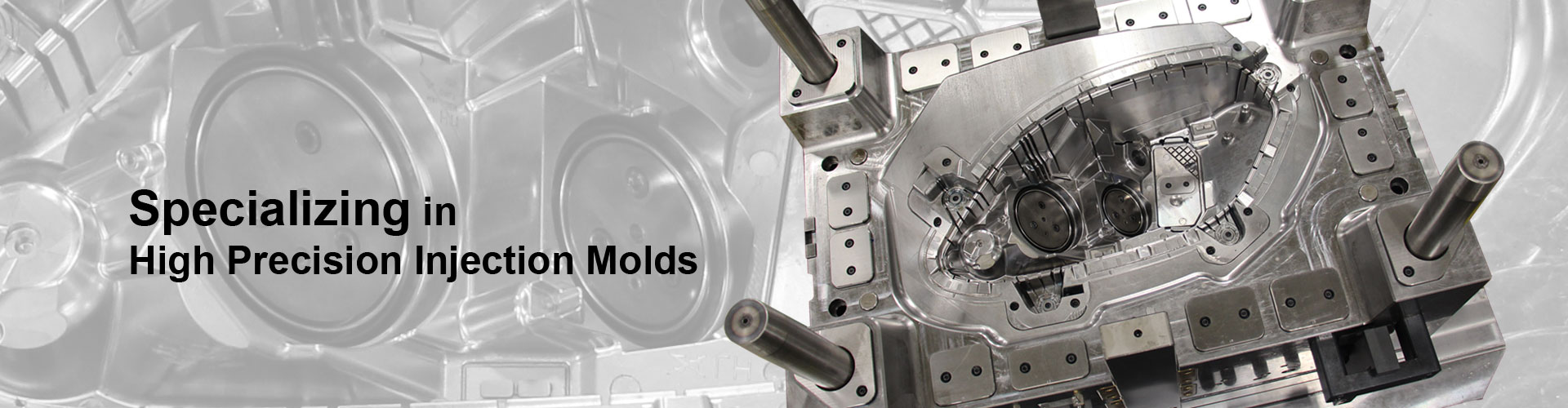

High Precision Plastic Injection Molds

The Platinum Tool Group manufactures a full range of injection molds including but not limited to; Thermoplastics, Thermoset, Multi-Colour (Rotational), Multi-Material, Transfer Molds, and Insert Molds.

Thermoplastic Injection Molds

Platinum Tool Technologies offers superior thermoplastic injection mold services for the production of a wide variety of plastic parts and components. Using the latest in technological equipment and innovative, cost efficient manufacturing techniques, our design and engineering team can provide you with variety of plastic injection mold options for your part and application needs.

Platinum Tool Technologies offers superior thermoplastic injection mold services for the production of a wide variety of plastic parts and components. Using the latest in technological equipment and innovative, cost efficient manufacturing techniques, our design and engineering team can provide you with variety of plastic injection mold options for your part and application needs.

The industries we serve include automotive lighting, automotive trim, consumer products, and electronics.

Injection molds created by the Platinum Team have been used by General Motors, Honda, Daimler Chrysler, Ford, Aston Martin, Toyota, Nissan, Harley Davidson, Volvo, Volkswagen, Land Rover and Jaguar.

Whether it’s a simple or complex custom injection mold project, Platinum can provide you with high quality thermoplastic injection mold services that include a quick turnaround time and on-time delivery.

Thermoset Injection Molding

Platinum Tool Technologies uses superior thermoset mold materials to manufacture a wide range of parts and assemblies for automotive, household appliances, and industrial market applications. Through advances in materials and processing, our thermoset molds used for high temperature applications deliver reduced cycle times.

Platinum Tool Technologies uses superior thermoset mold materials to manufacture a wide range of parts and assemblies for automotive, household appliances, and industrial market applications. Through advances in materials and processing, our thermoset molds used for high temperature applications deliver reduced cycle times.

With more than 200 years combined thermoset mold manufacturing expertise, Platinum Tool can assist in the design, material selection and production of your mold to ensure high quality results. Our thermoset mold capabilities include:

- Thermoset Injection Molds

- Thermoset Compression Molds

- Thermoset Insert Molds

The thermoset molding materials we specialize in include, bulk molding compound (BMC), therrmoset polyester, vinylester, sheet molding compound (SMC), phenolic (Bakelite), meamine, urea, diallyl phthalate (DAP), and epoxy.

At Platinum Tool, we combine our experience, state-of-the-art technology, and commitment to quality to produce molds that manufacture durable plastic parts for our customers.

Multi-Color / Multi-Material Molds

Platinum Tool is a leader in the manufacturing of multi-color and multi-material thermoplastic molds. Together, with our vast experience, state-of-the-art technology, and cost efficient manufacturing techniques, the most complex projects are made simple.

Platinum Tool is a leader in the manufacturing of multi-color and multi-material thermoplastic molds. Together, with our vast experience, state-of-the-art technology, and cost efficient manufacturing techniques, the most complex projects are made simple.

Typical applications for our multi-color and multi-material mold technology include automotive lighting, seating, interiors, appliances and consumer products.

Platinum’s experience in producing multi-color and multi-material molds stretches over several decades. Adding multiple colors, combining different kinds of materials, and applying soft touch layers over complex components is part of a process that is performed on a daily basis.

Transfer and Insert Molds

Put our expertise in Insert and transfer molding to work for you to reduce or eliminate secondary assembly of your final product saving you time and money.

Many applications that require multi-color and multi-materials are not suited for the more complex and expensive rotational tools we produce.

Many applications that require multi-color and multi-materials are not suited for the more complex and expensive rotational tools we produce.

For low volume requirements the manufacture of multiple tools and inserting and over molding or merge molding are a more practical and cost effective solution.

For mid range volume parts the solution of transfer molds of more than 1 part in the same mold is a cost effective solution to meet your customer’s demands. By using a robot to pick and place multiple parts within the same mold you can reduce your labor and cycle times to achieve in mold assembly, over molding and merge molding.

With our teams have vast experience, we can assist you with your product design, engineering, manufacturing solutions and elastomer selections.